Process

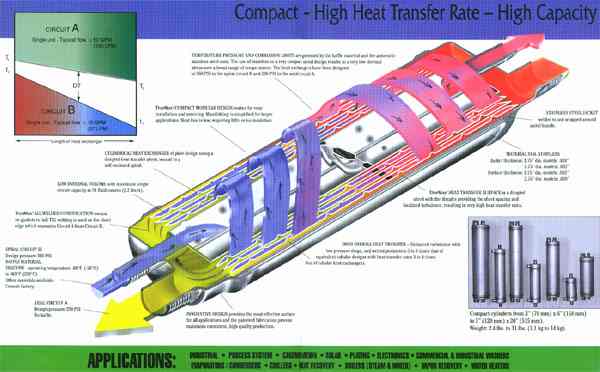

Technology’s TherMax2 Heat Exchanger is a

state-of-the-art in-line stainless steel exchanger for deionized water and

process solutions. This revolutionary design is constructed of a 316L stainless

steel jacket and spiral bundle. Internal silicon baffles and a dimpled spiral

sheet route water in a rotating circular motion, resulting in high heat transfer

(other baffle materials are available to suit your specific needs). The heat

transfer surface of the TherMax2 enhances

turbulence with low pressure drops, producing heat transfer rates 3 to 4 times

that of tubular heat exchangers.

The all-welded construction provides not only long life, but easy installation as well. There are numerous applications for the unit including industrial, process system, cogeneration, solar, plating, electronics, commercial and industrial washers, evaporators/condensers, chillers, heat recovery, boilers (steam and water), vapory recovery, and water heaters.

Features:

| Jacket thickness: | 3.75 inch diameter models: | .039 inches |

| 2.75 inch diameter models: | .032 inches | |

| Surface thickness: | 3.75 inch diameter models: | .032 inches |

| 2.75 inch diameter models: | .020 inches |

Click on illustration to see enlarged version (it is a large file and may take a

moment to load).

|

THERMAX2 HEAT EXCHANGERS |

||||

|

EXCH. AREA (Sq. Ft.) |

OVERALL LENGTH In./(mm) |

DIM. DIA. In./(mm) |

MODEL NUMBER |

SHIP WGT. Lbs./(kg) |

|

1.1 |

6.25 (159) |

2.75 (70) |

IS1.1-2.75-6.25 |

5 (2.5) |

|

2.5 |

10.25 (261) |

2.75 (70) |

IS2.5-2.75-10.25 |

7 (3) |

|

3.8 |

14.25 (362) |

2.75 (70) |

IS3.8-2.75-14.25 |

10 (4.5) |

|

3.8 |

10.75 (273) |

3.75 (96) |

IS3.8-3.75-10.75 |

15 (7) |

|

5.8 |

15.50 (394) |

3.75 (96) |

IS5.8-3.75-15.5 |

20 (9) |

|

7.8 |

20.25 (515) |

3.75 (96) |

IS7.8-3.75-20.25 |

24 (11) |

|

15.0 |

20.25 (515) |

4.75 (121) |

IS15.0-4.75-20.25 |

30 (13.5) |

For more information, prices and availability please visit our contact page.